Overview

Durability Redefined, Weight Perfected

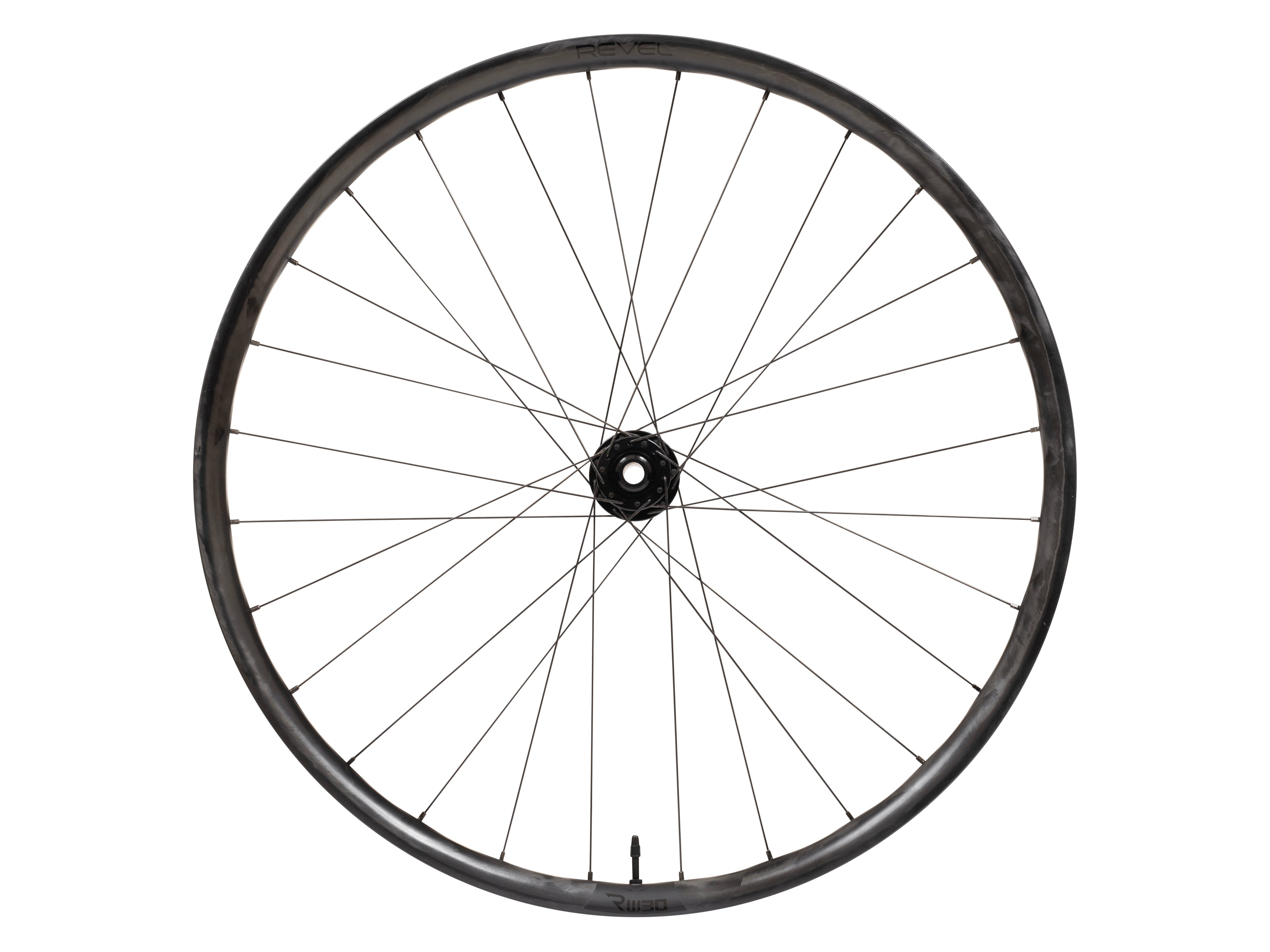

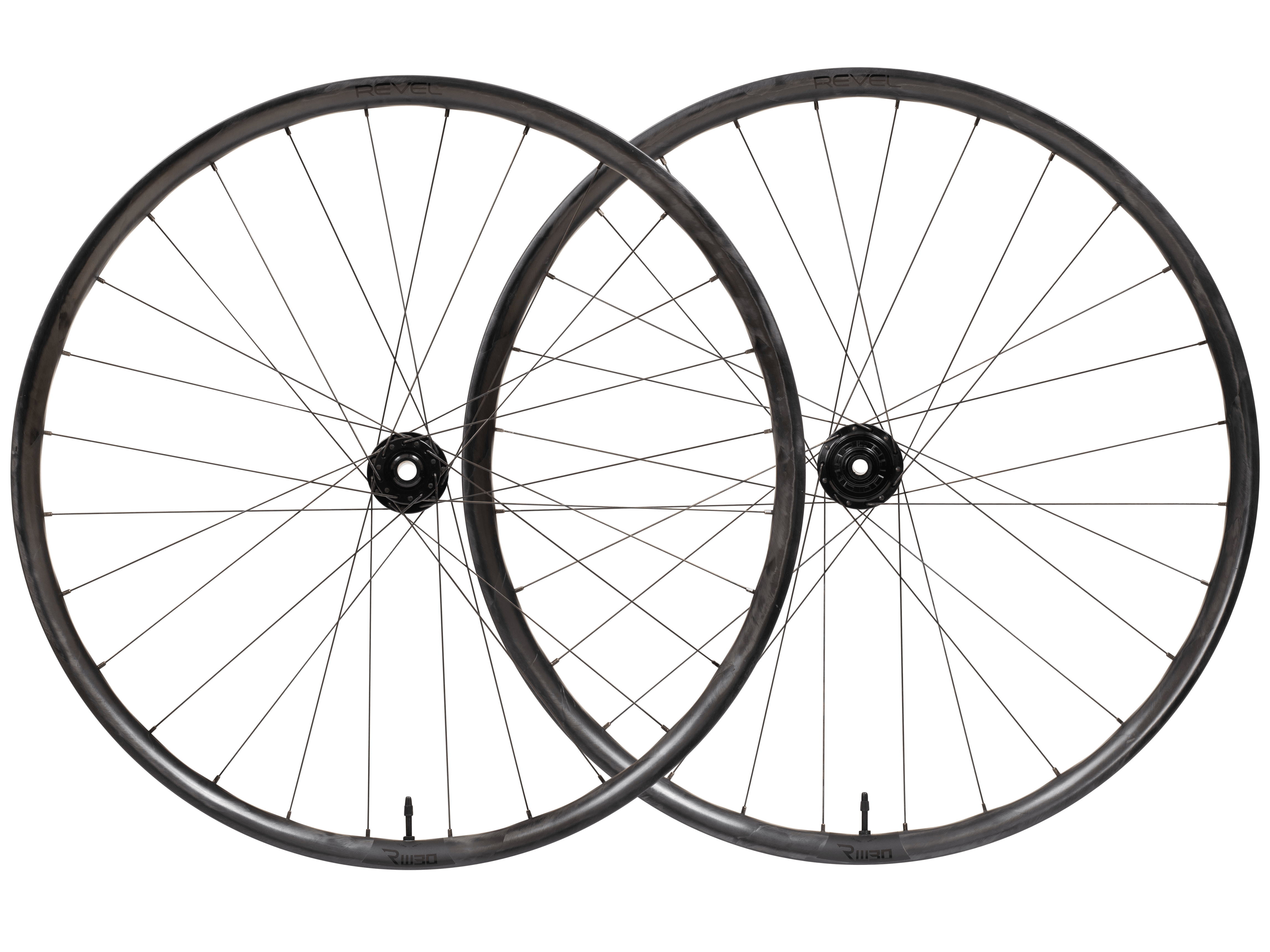

The RW30 offers a best-in-class ride quality while maintaining the strength and durability necessary to take you the distance on buffed single track in CB, big chunk in Moab and everything in between. A perfected width complements a fine-tuned Fusion-Fiber™ layup ensuring a quieter, smoother ride without sacrificing weight. An increased width reinforces durability, maintaining flexibility where necessary places these carbon wheels in a league of their own. Goodbye to the days of a reactive wheel- these RW30s are engineered to every last detail ensuring a consistently smooth ride, regardless of the trail ahead.

Using the most advanced and sustainable technology available, Revel continues to push the boundaries of what is possible in the bike industry. As the first bike company in the world to use Fusion-Fiber™ technology, Revel’s years of experience, trials, errors, and successes have perfected the details that matter. Engineered in Colorado and built in Utah, these entirely American made wheels are just one of the small actions Revel is taking to continue to bring the bike industry and sustainability together. With a lifetime guarantee, you can leave your worries at home knowing should the wheel become compromised, a new one is just a phone call away.

Welcome Revel R30- your ticket to a superior trail adventure.

Fusion-Fiber™ is the name for this technology, which encompasses the material and the process. And it's unlike any composite material the bicycle world has ever seen.

Learn More »Build Options

From: $799.00

Wheel

Build Specs

| RW30 Specs | RW30 29" | ||

|---|---|---|---|

| Wheel size | 29" | REC. TIRE WIDTH | 2.3 - 2.6" |

| Internal Width | 30mm | FRONT END CAPS | Ships w/ Standard Only *Torque compatible |

| External Width | 38mm | Driver Body Options | XD | MS |

| Rim Depth | 24mm | Single Rim Weight | 485g |

| ERD w/ Sapim MG Washers | 592mm | Hub Spacing | 15x110mm front 12x148mm rear |

| Spoke Count | 28 Hole | Complete Weights | I9 Hydra : 1,850g |

The wheels do seem to do a good job of damping trail chatter, especially at high speeds, and there is something unique about the way they ride compared to other carbon wheels that I've been on. Read more...

The RW30 rims shrug off impacts from roots and rocks quietly and confidentlyand don’t let out a stomach-turning clack that I’ve experienced with other carbon rims. After a solid year of riding with next to no maintenance, the rims continue to roll smoothly and dead straight, which is all you can really ask for. Read more...

They’ll give you that extra level of support and deft handling that everyone loves about carbon hoops, but without the harshness or loss of control that comes along with most. They’re compliant enough to really notice an improvement in ride quality and cornering control, but not so stiff that they’d knock me off line. That combination makes for the sensation of cornering like you’re on rails. Read more...

Bottom line: the material properties of Fusion-Fiber™, in concert with quieter Hydra hubs, make for a very quiet ride thus far. Read more...

Wheel specs

RW30

29"Recommended Build Specs:

- Ideal Spoke Tension: 120kgf

- Safe Spoke Tension Range: 110-130kgf

- 2x or 3x spoke lacing only

- Sapim MG Washers required for all builds

- Compatible Nipples: Sapim Double Square Brass, Sapim Polyax Brass, DT Swiss Squorx Brass or Pro Head brass (Brass nipples only)

- Contact Revel sales and service with questions regarding build criteria

Rim Specs

- Symmetric angled spoke hole drilling

- Fully Recycleable

- Lifetime Guarantee

The Details

Design Features

Support

Frequently Asked Questions

Yes! And recycling is important!– Our FusionFiber™ wheels are backed by a lifetime guarantee – should you bust a wheel, send it in and we’ll send you a new one, no questions asked. Once we receive your wheel, we will remove the vinyl decals and drop the rim into a chipper to chop it into pieces for recycling.

Lifetime for the original Owner. If you break a wheel, we will do everything we can to get your wheel to us, fixed, and back to you as soon as possible.

Yes, just be sure to use the provided Sapim nipple washers and brass nipples, and follow our build directions. Also we highly recommend Sapim Spokes! Or check out out some of our favorite authorized wheel builders!

We include everything to get this set up Tubless(Valve, and Tape) as well as nipple Washer and Nipple (must use to qualify for warranty).